- Home

- Products

- Motion Control

- Motorized Stages

- Motorized Rotation Stages

- General Motorized Rotation Stages

- WN05RA400M General Motorized Rotation Stages

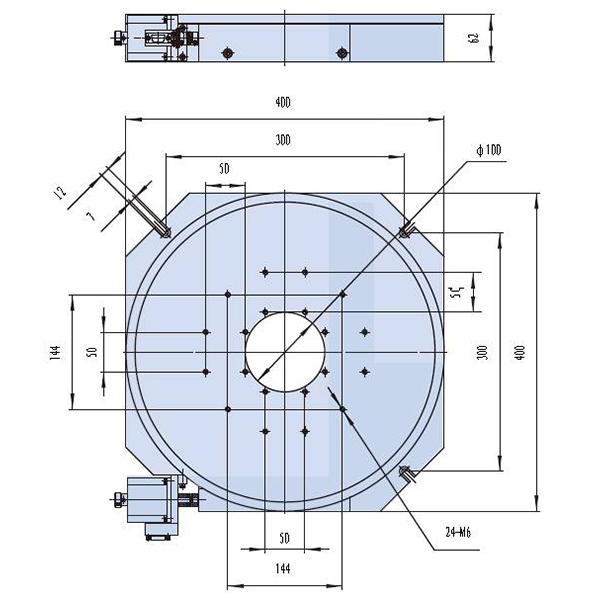

WN05RA400M General Motorized Rotation Stages

WN05RA400M General Motorized Rotation Stages is suitable for providing rotational displacement by electric control in automatic displacement control in scientific research, full-automatic measuring and testing equipment, industrial automation and other fields. This precision stage could be used horizontally or vertically, and could be combined with other motorized stages to form integrated multi-axis stages.

Parameter table WN05RA400M General Motorized Rotation Stages

Structural parameter| Angle range | Table size | Transmission ratio | Guide type | Stepper motor (1.8°) | Center load capacity | Weight |

| 360° | φ400mm | 720:1 | bearing | SST57D3301 | 75kg | 21kg |

| Resolution | Speed | Repeatability | Positional accuracy | Run-out of top plate | Backlash | Eccentricity | Step-out | Driving parallelism | |

| 0.0025°=9″(Non-MS driver) | 0.000125°=0.45″(20 MS driver) | 5°/sec | 0.002°=7.2″ | 0.005°=18″ | 20µ | 0.005°=18″ | 30µ | 0.005°=18″ | 120µ |

- Equipped with standard stepper motor and RS232 interface, the WNSC series motion controller which was independently developed by BJWN can realize automatic control.

- The motor shaft is made by several precision processes, ensuring high precision, high load and long service life.

- Precision worm and worm gear structure for stable operation; the motorized stage could rotate forward or backward with minimal backlash.

- Because of delicate backlash eliminating structure, the backlash caused by long-term operation can be adjusted.

- The special design could ensure the extremely run-out and eccentricity of the precision stage, making the rotation more stable.

- The central hole and rotating center of the rotation stage meet the strict requirements of coaxial degree, and the central aperture of the rotation stage has strict tolerance limits, easy for customers to do precision positioning.

- The scale along the outer edge of the motorized stage's platform is a laser marking ruler, and the ruler could rotate relatively to the rotation stage, easy to initial position and read.

- Connected the stepper motor and worm by high quality flexible coupling, good for eliminating eccentricity and greatly reducing eccentricity disturbance, lower noise.

- Could increase the speed and torque by replacing with the 3-phase motor or servo motor.

- The precision rotary stages could be customized, such as adding limit function, setting the initial zero, changing the servo motor, and adding the rotary encoder.

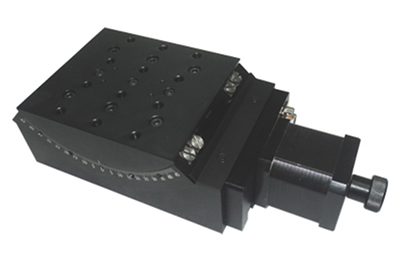

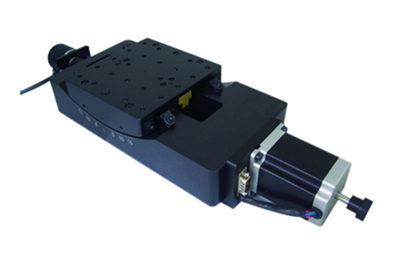

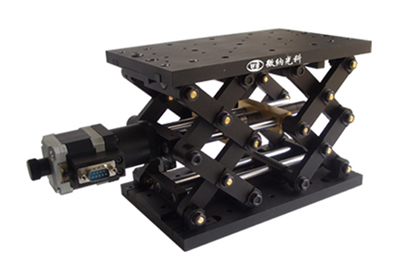

Related Products

Inquiry Form

Beijing Winner Optical Instrument Co.,Ltd.

Add.: Floor 3, Block 6, Laser Industrial Park, Anshan High-Tech Zone, Liaoning Province

Tel.: +86-10-61509982

+86-10-61507993

Fax: +86-10-61569408