- Home

- Custom Made

- Manufacturing Capability

There are more than 70 skilled technicians in BJWN, a number of advanced CNC machining centers with more than 20 processing machines. The powerful production capacity and technical department ensure that the equipment and accessories can be produced according to the actual needs of the customers, which ensures products have high quality and makes the daily production achieve 300 pieces.

Machining equipmentOur company has more than 20 pieces of machining equipment, which guarantees the product precision at many dimensions effectively.

Lathe

The lathe processes raw materials to accessories such as table, motor plate and precision screw.

CNC Machining Center

milling, boring and drilling and other processes will accurate to the micron level to ensure the quality of the products when processing components such as complex curved plates, special-shaped parts, Plate and sleeve part and so on..

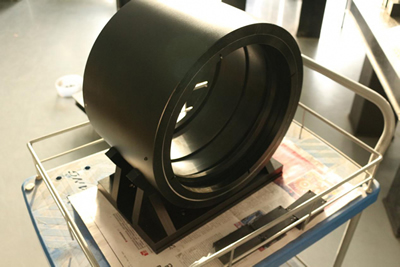

Surface treatment

We also introduced large-scale sand blasting and oxidation technology to treat the outer surface of the parts to make sure the parts are highly corrosion-resistant and more beautiful. For example, the surface treatment of the aluminum alloy is black anodizing, and for stainless steel is anodizing.

Assembling and adjusting of parts

After the surface treatment, the experienced workers will combine the qualified parts into components or products according to the technical requirements. After assembling,parameters such as repeatability, straightness and parallelism will be tested to ensure that the product meets all technical requirements.

Shipment

We will select out the qualified products and use the multilayer corrugated case or wooden case to pack them according to customer requirements. We will also fill in enough buffer to prevent damage during transportation, and finally contact the long-term cooperated well-known logistics enterprises to do shipment and transportation.